What is relining?

Relining is the repair of sewers, air ducts, and flue gas exhausts by remotely applying a new seamless pipe within the existing pipe.

No demolition or excavation?

No, relining effectively creates a new pipe inside the old one. The only requirement is suitable access. In any case, there’s no need to break open structures to address a leak, blockage, or damage point.

Is excavation necessary?

Rarely. In some cases, it may be required, but relining can often be performed via the outdoor sewer connection, the main standpipe, or another drain, eliminating the need for excavation altogether..

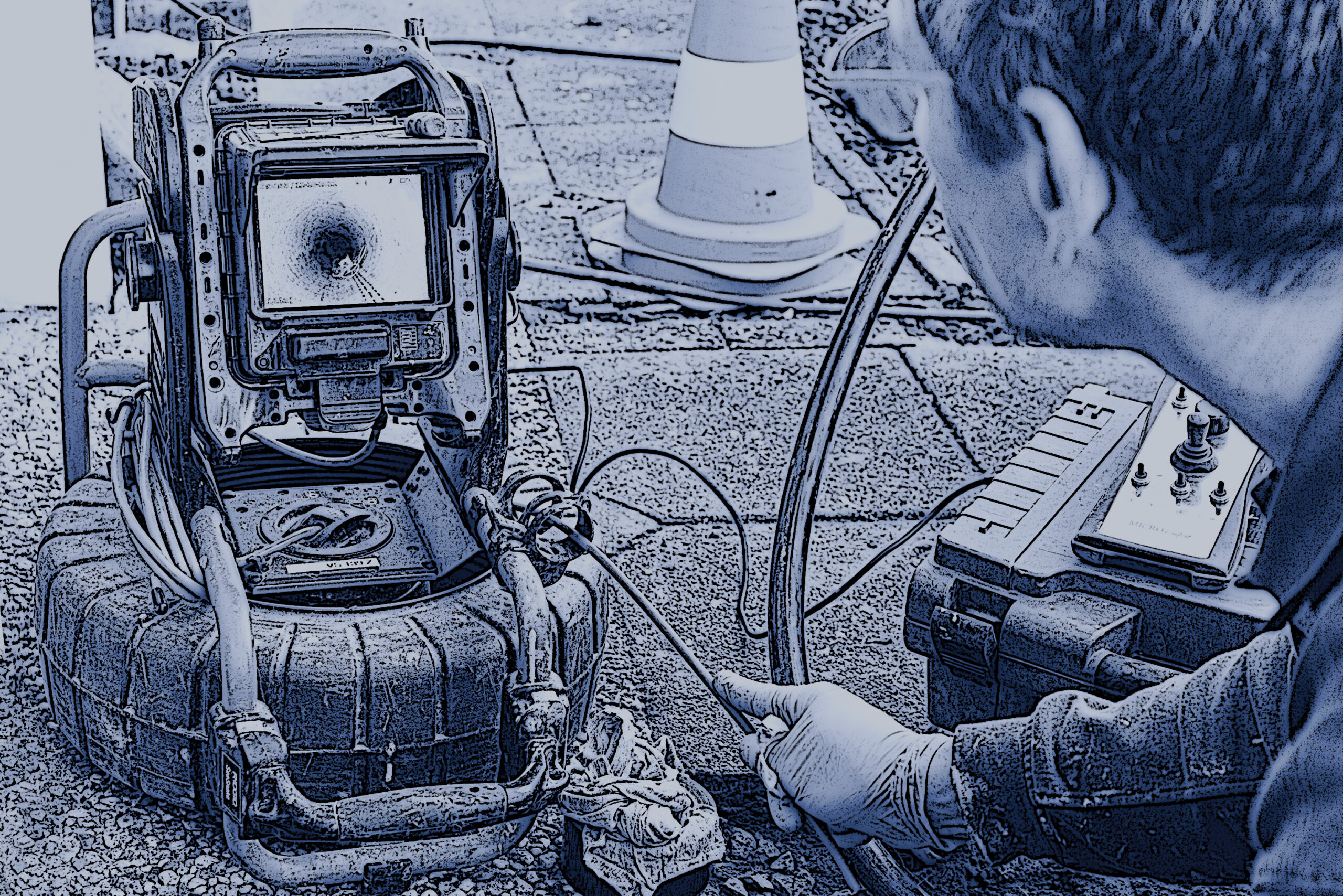

How do you locate the damage point?

Using cameras with a 360° rotatable head, we can pinpoint any leak, sagging, or blockage. We take photos and map the entire drainage or piping system using a 3D program and AI. This allows you to see exactly what the issues are and their precise locations.

Doesn’t that take a lot of time?

No, locating and mapping the issues takes a few hours at most. The relining process itself also takes a few hours. This means the problems can often be resolved on the same day.

Relining in action

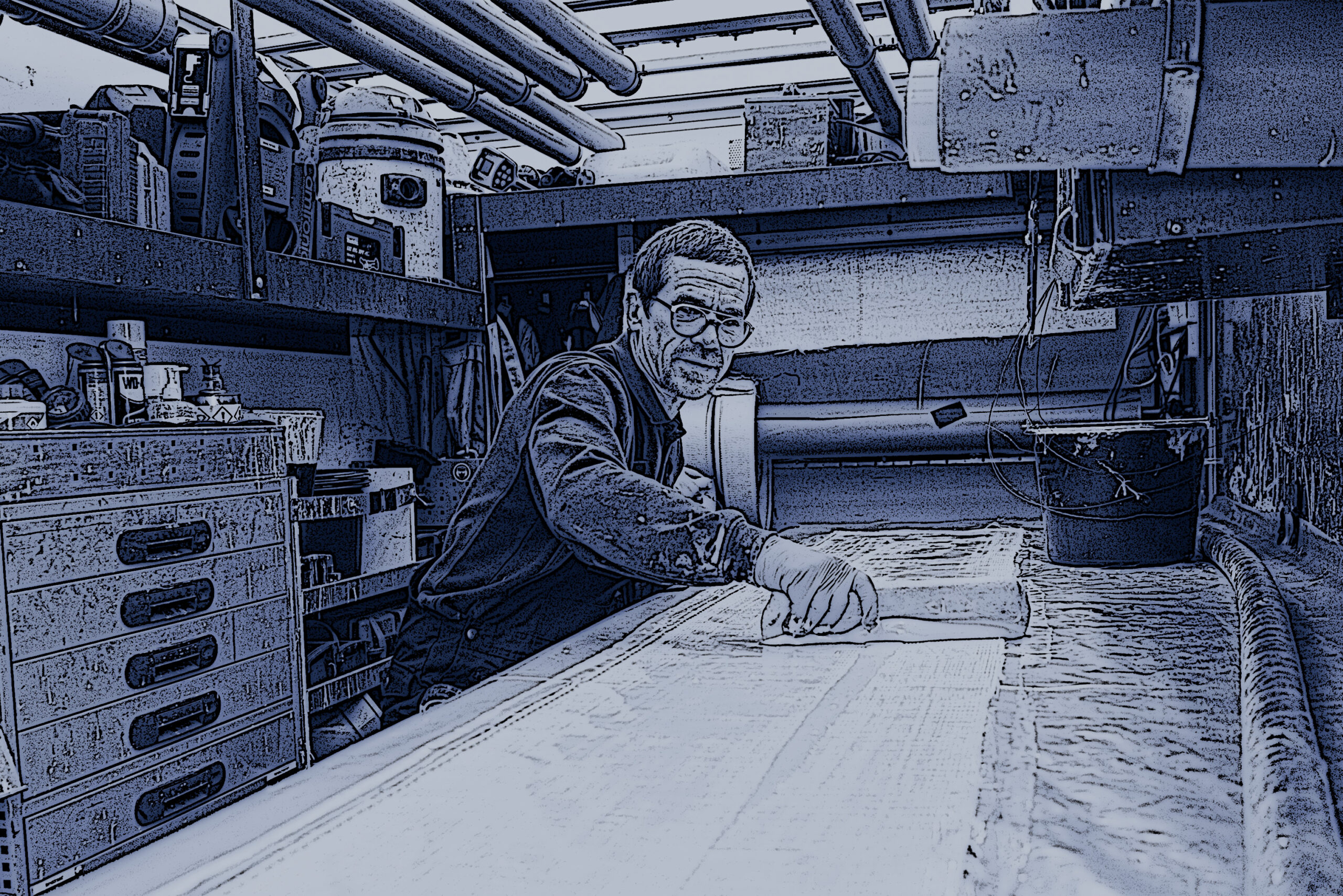

PREPARATION

The outdoor sewer connection is exposed to insert a remotely controlled camera. This is also the point where the relining, in this case a packer, will be introduced.

LOCATING

Thanks to the 360° rotatable camera, we obtain crystal-clear color images of the sewer system. We use these to map the piping system and convert it into a 3D visualization with the help of AI (artificial intelligence) and 3D software. This allows you to see exactly where the issues or obstructions are located.

Based on this, we provide advice and discuss the necessary steps.

MILLING/GRINDING

Where necessary, the pipe is cleaned and cleared of buildup caused by age and use. This can be done through milling, grinding, or knocking. A rapidly rotating head with specialized tools is inserted, removing irregularities through a cutting motion. Loose material and debris are then flushed away under high pressure.

FOR PACKERS: RESIN APPLICATION

Reline Specialist primarily uses so-called ‘packers,’ a proven method. A fiberglass fabric or sleeve is custom-made, then impregnated with an exceptionally strong, waterproof two-component resin that hardens within an hour, becoming impervious.

PREPARING THE PACKER

The exact location in the system where the new pipe will be placed is measured and determined in advance. Sometimes the entire system is treated, while other times it’s a partial renovation. The new pipe with the packer (commonly referred to as the packer) is now inserted into the sewer and set in place using air pressure.

PACKER READY FOR USE

The exact location in the system where the new pipe will be placed is measured and determined in advance. Sometimes the entire system is treated, while other times it’s a partial renovation. The new pipe with the packer (commonly referred to as the packer) is now inserted into the sewer and set in place using air pressure.