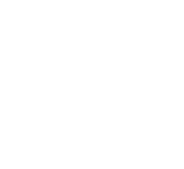

Damage to your air duct, sewer, or flue gas exhaust?

We’ll fix it!

(without demolition or excavation)

ENVIRONMENTALLY FRIENDLY SOLUTIONS

Relining, pronounced ‘ray-line-ing’ or ‘ree-line-ing’. Relining contributes to a better environment. No new materials are required, and no excessive CO2 emissions are produced.

INSPECTIONS, REPORTS, AND ADVICE

We provide thorough reports based on video inspections. Additionally, we offer advice on necessary measures and required repairs.

EFFICIENT AND

FAST REPAIRS

Virtually all repairs can be completed within a day thanks to our relining technology combined with AI. By the end of the day, everything is fully functional again.

NO DEMOLITION OR

EXCAVATION

We renovate your sewer or piping system remotely without the need for demolition or breaking inside the building. Excavation outside the building is rarely required.

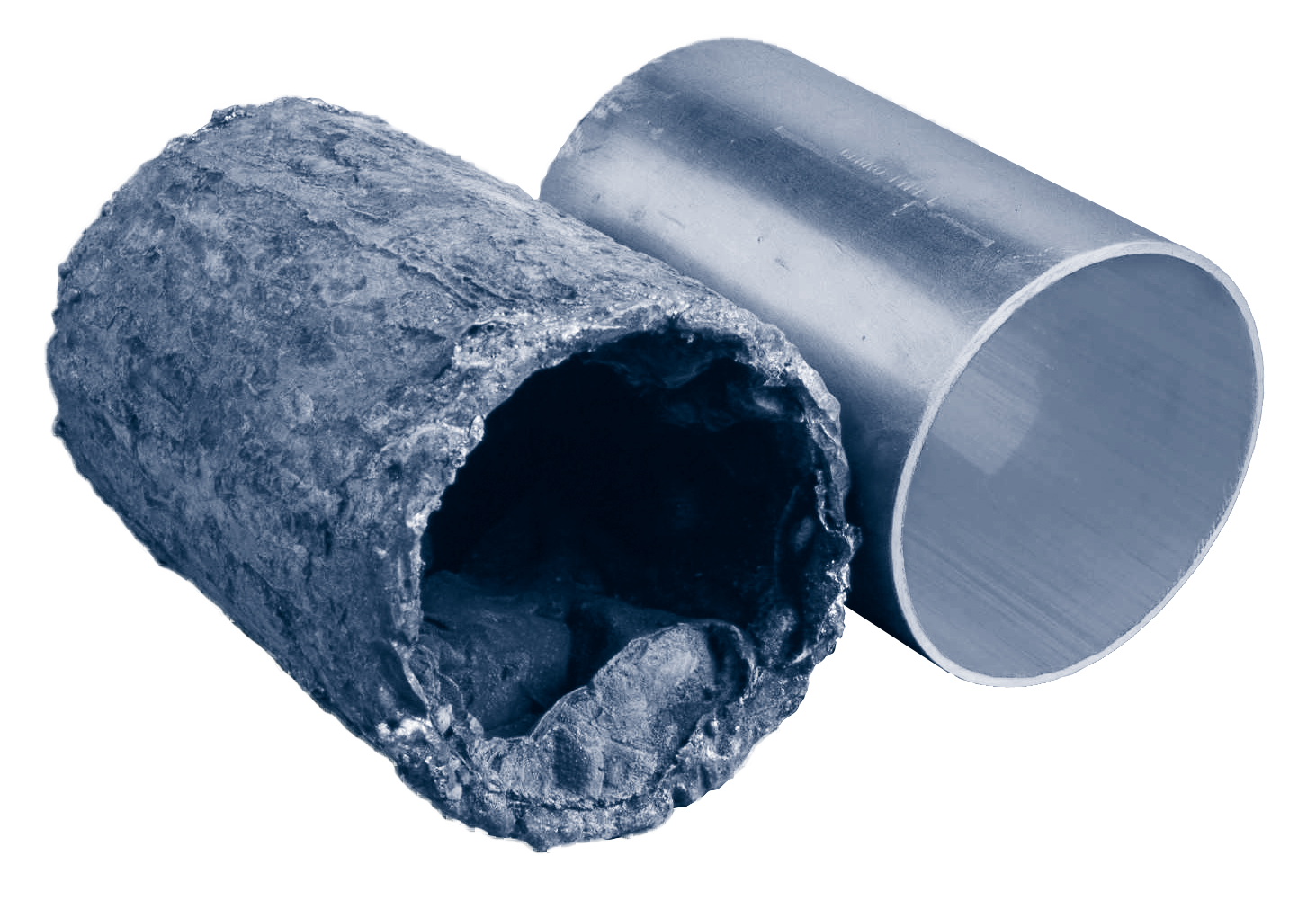

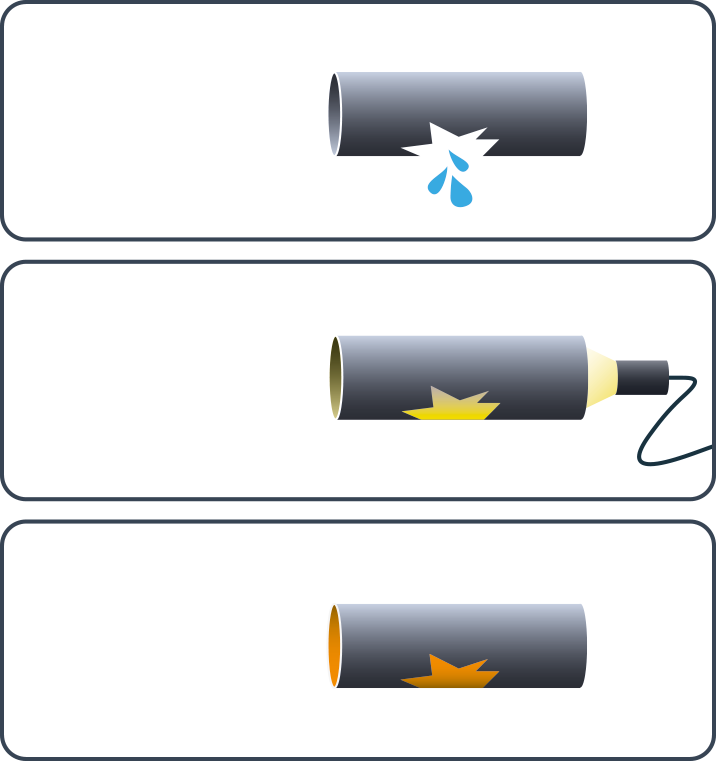

A SMOOTH AND SEAMLESS PIPE OR DUCT

A pipe is restored by applying a specially developed coating, ensuring a watertight and airtight seal.

RRelining is the remote repair of sewers, air ducts, and flue gas exhausts (FGEs).

HISTORIC BUILDINGS

In historic buildings, sewer systems often consist of cast iron pipes, sometimes even with lead ends connected to kitchen and bathroom drains. Cast iron is naturally prone to corrosion, especially in humid environments. Over time, this leads to rust formation and buildup, causing severe blockages or leaks due to deformation.[geschiedenis riool en riolering]

POST-WAR RECONSTRUCTION

In the 1950s and 1960s, asbestos pipes were used instead of cast iron. Asbestos was a cost-effective and durable material, also resistant to acids. At the time, asbestos was widely used in construction. Removing these pipes is not immediately necessary, but after decades, they become brittle, increasing the risk of cracks or damage.[geschiedenis riool en riolering]

THE SEVENTIES

Since the 1970s, PVC pipes have been predominantly used in the construction of new homes. Research by TNO indicates that modern PVC has a lifespan of 100 years. However, in the 1970s and 1980s, lower-quality PVC (with lower gelation degrees) was used. The crack resistance of these pipes is significantly lower than PVC with a gelation degree of 60–85%, leading to cracks and breaks. [geschiedenis riool en riolering]

NEW CONSTRUCTION

The use of PVC and PE in new construction is standard and rarely causes issues. However, improper installation, such as not fully supporting pipes in poured floors, can lead to cracks. Another issue involves underfloor pipes in crawl spaces that are not properly or fully suspended, causing sagging and, eventually, breaks and blockages.[geschiedenis riool en riolering]

If you experience a leak or other issues (sewer flies, odors, or blockages), we locate the problem using 360° rotatable, remotely controlled high-tech cameras..

These cameras are inserted via, for example, the horizontal underpipe, standpipe, or various drains from the bathroom, kitchen, or toilet.

We then map the piping system and identify the locations of the issues.

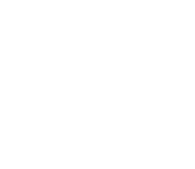

The relining process involves locating a blockage or leak, followed by the relining itself. The sewer or pipe is then cleaned to prepare for relining. The pipe is flushed and cleaned under high pressure. Buildup and irregularities are scraped away using chain knockers and rotating brushes.

Next, the relining process begins. A flexible fiberglass sleeve is impregnated with a fast-curing resin. The so-called packer is carefully inserted at the damage site. Once the packer is in place, air pressure is used to shape the sleeve into the pipe.

Thanks to relining, the old pipe is effectively replaced by a new, high-quality pipe.

Reline Specialist offers sustainable and cost-effective solutions for issues with sewers, air ducts, and pipes. Without demolition or excavation!

Thanks to professional and efficient inspections and preparation, we deliver tailored work. Call us at +31 6-18 62 19 60, email us or use the contact form.

Click here for all company details.